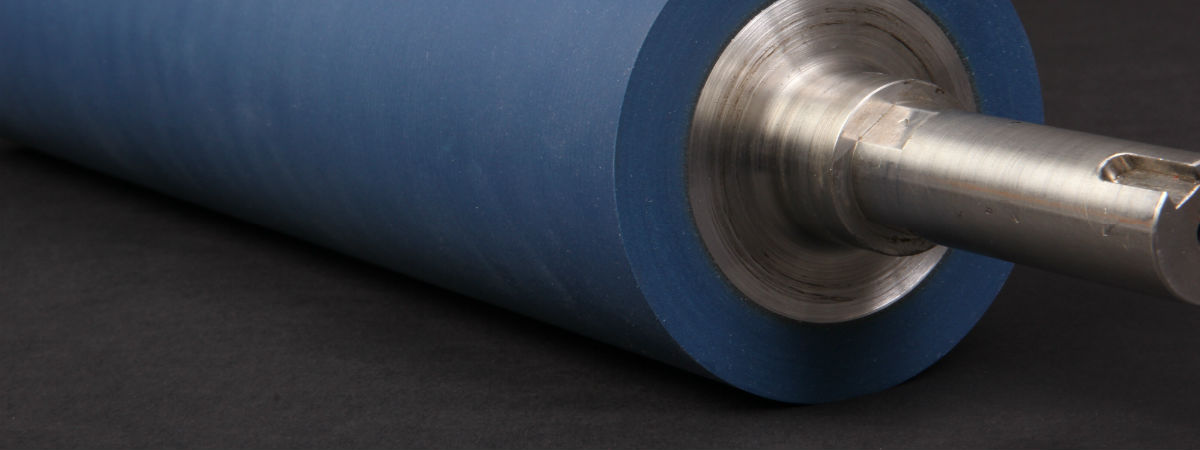

Rubber Roller Manufacturer

Industry Specialists with an Average of 35 Years Experience

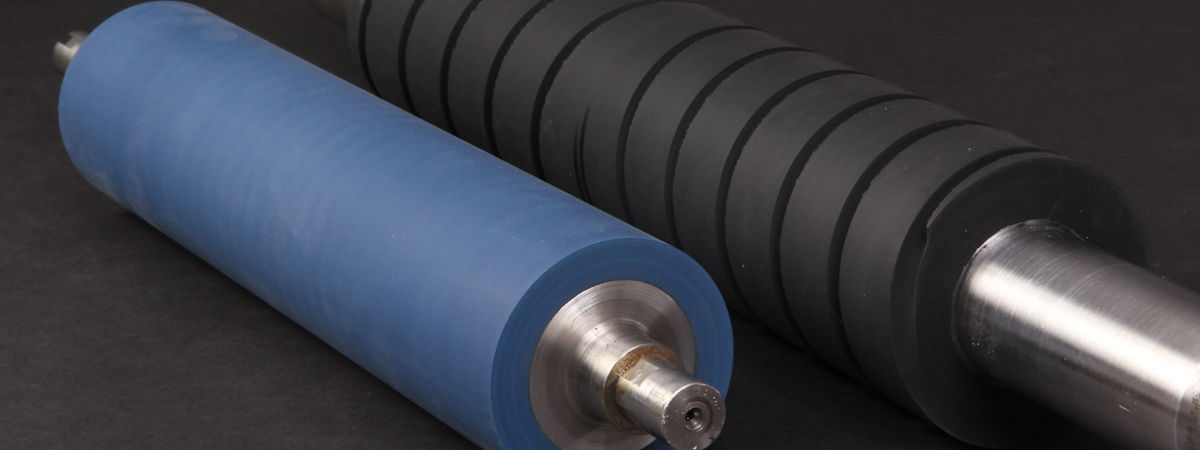

Rubber Right Rollers’ core business is rubber roller manufacturing and recovering. We are capable of manufacturing rubber rollers from .125” wide to 160” wide in a vast array of materials, colors and durometers. Our rubber roller covering capabilities include calendar building, strip building, cross head extruding, compression and transfer molding.

We strongly believe there can be no compromise when it comes to technical competency in the design and manufacture of rubber rollers. We constantly examine every detail of our customer service and quality control to provide you with a cost effective and superior roller.

We also offer custom rubber molding, grinding, and a variety of other machining services. You can find our full list of capabilities here.